AQUA HOT ZONE MOTOR REPLACEMENT

Model AHE-100-04S

Manufactured 8-04, Diesel - 50,000 BTU, Hr. on unit 2142.1, 1-4-2016

This is a tutorial on how I replaced the two circulating pumps, Zone 1 & Zone 2. The system was still working ok inside the coach with heat coming out of all zones. The sound I noticed outside was that the zone motors would start up and then run full speed for a second and then slow down and speed up constantly. They would not run at full speed. This unit was built in 8-04, the motor/pump is an obsolete pump and is no longer available. The replacement pump is not a direct replacement pump.

The retrofit kit had these parts pictured below; I forgot to take a picture of the bag when I got then.

All of the parts less (2) Pumps, (1) Formed Hose, (3) Hose Clamps (2) Pig tails for pump I used in the installation. The rest of the parts in the left picture x 2 are left over parts!

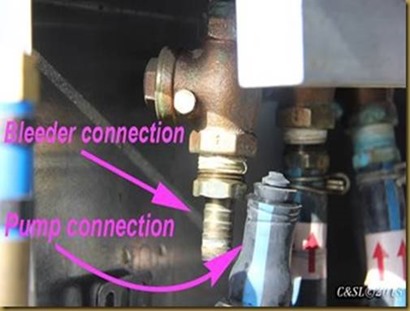

This installation was not difficult to do. I did not drain the system. I did cool it down and just clamped off the inlet hose by the heater on the first pump and disconnected the line above the bleeder fitting going to the registers and capped it off there. The second pimp I just removed the hose from the bleeder fitting and heater and plugged the pipe coming out of the boiler.

Then removed the hose clamps and (3) bolts holding the pump to the bracket. There were (4) rivets holding the bracket to the heater.

The most difficult part was to removing the old pump brackets as they were pop riveted to the heater housing because I could not get to the back side to drill them out, I had to grind the rivet part off from the inside of heater.

I did not use the bracket that came with the pump kit, as the pump would have not lined up with the hose going up to the bleeder fitting in the top hole. Once I got the brackets off I had to modify the bracket, as you can see that the bolt holes did not line up correctly.

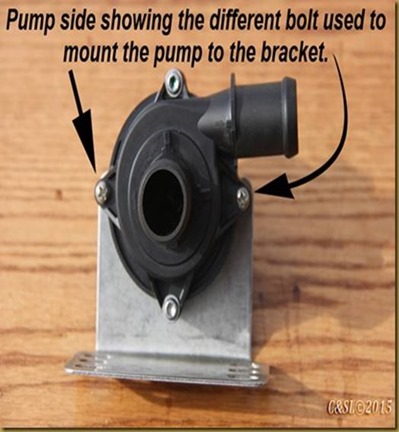

To have the holes line up with the pump, I ground the bracket out so the pump would fit farther in the bracket, about 1/8” deeper. To mount the pump to the bracket I had to remove (2) of the screws from the new pump and (2) two machine bolts from the old pump and use them instead of the screws. They were the right size and length to go thru the new pump body, bracket and for a nut to be used. The bracket had to be mounted on the back side of the pump to line up the hose out the top. I only used 2 bolts to mount the new pump to the bracket, as I was told by the suppliers of the retro fit kit to just use a zip tie to hold it to the old bracket. Not a chance!

This new pump has ¾” size hose ends and the old pump had ½” size hose ends. As you can see in the first picture, I just slip the ½” hose over the ¾” hose end on the pump (with a little work,) the air bleed fitting was ½” so it fit. I also used the old ½” hose from the heater to the new pump ¾” end. After I had the inlet hose on, I had to slide the pump back behind the 2 hoses for the other zone pumps in the second picture. The 3rd picture is the hose that will be connected to the air bleeder fitting. The 4th picture is connecter & bolts in place. I used bolts, not rivets, for easier removel the next time, Lol.

This is the pig tail to connect the pump to the harness. The red pump wire is the positive (female end) same as old pump. It connected to the Purple (male end) harness wire. The negative wire on the old pump was blue wire, the new pump wire is black (male end) is connected to the white (female end) harness wire.

The zone 2 pump was basically the same installation as the first pump, but I used a new form fitted hose supply with the kit. I removed the hose from the tank and installed the new hose. I had to cut the new hose to length; it took two times to remove it and cut the hose to get it to the right length. I lost less than a cup of boiler antifreeze in this process. You can see the nice shiny black hose at the boiler connection.

This is what the end project looks like before clean up.

Some of the things I would have done different the next time below.

OVERVIEW OF THE INSTALLATION PROJECT.

- I would not have disconnected the top line above the bleeder.

- I would have replaced the fitting in the bleeder fitting with a ¾” fitting.

- I would have removed the hose from the boiler tank and plug the line at the boiler I would have used the ½” to ¾” supplied formed hose. Was worried about damaging the fitting in the tank when removing the hose from the tank.

Overall this project took me about 6 hrs. to do. I was very cautious, working slowly on a very expensive unit to replace if I screw up something. I also did this repair way out in the desert boondoocking with only the parts and tools I had in the coach.

I did try to dissemble the old motor to get to the printed circuit board to see if I could figure out what failed and caused the motor to surge faster and then slow down. The magnet side is pressed onto the shaft and I do not have the right tools to remove it at this time.

All text and photos found on followusinourtravels.blogspot.com is copyrighted and may not be published, rewritten or downloaded without permission of the owner of followusinourtravels.blogspot.com. and C&SL photos. All Rights Reserved. ©Follow Us In Our Travels 2012 - 2016

No comments:

Post a Comment

Comments are moderated, and will not appear until the author has approved them.